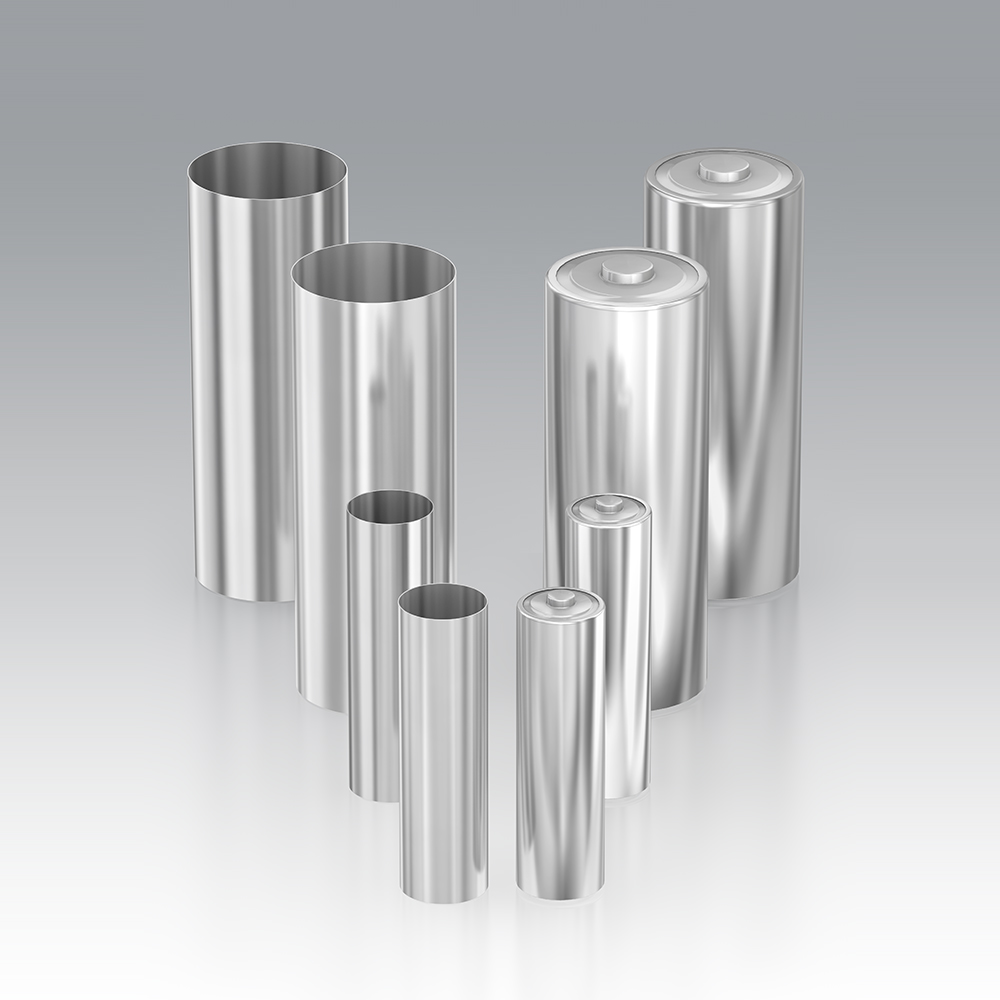

Order for battery cell housing production line – Schuler Group

Schuler to supply turnkey line to US site of South Korean manufacturer LT Precision South Korean manufacturer LT Precision has ordered a line for the production of battery cell housings. © Schuler Göppingen, 9 January 2023 – [...]