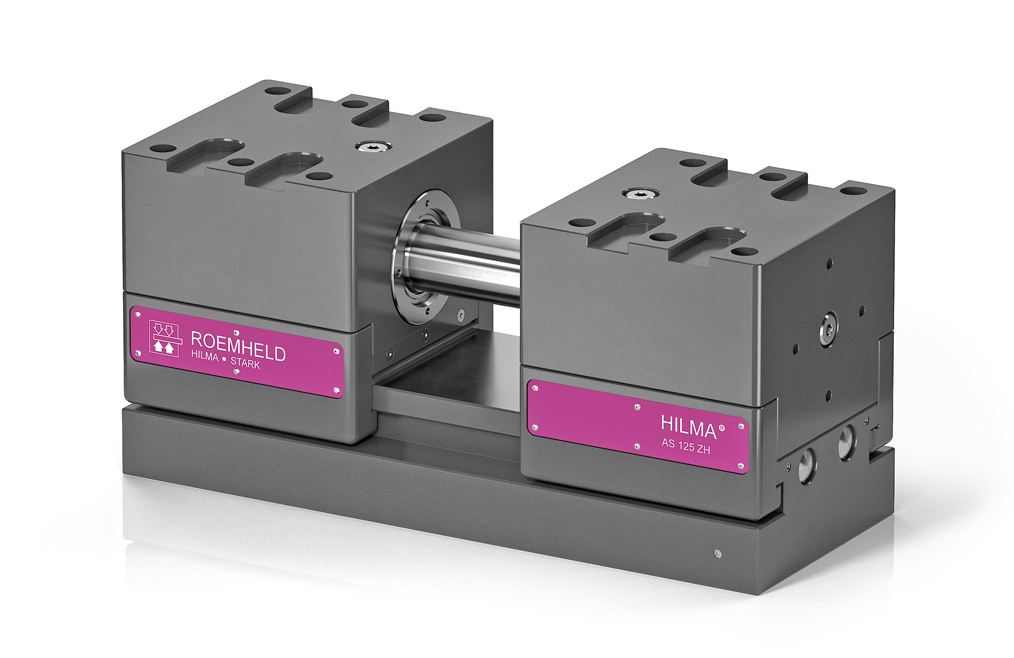

A hydraulically-actuated, double-acting clamp with a long-travel, ideal for workholding in production systems having robotic or otherwise automated component load / unload, has been introduced by Roemheld. It will be shown for the first time on the German manufacturer’s stand at AMB 2022 (13th – 17th September, Stuttgart, Hall 1, Stand H70). Availability in Britain and Ireland is through Roemheld UK, Hitchin (www.roemheld.co.uk)

Roemheld’s new HILMA.ASH clamp has an 80 mm stroke for accommodating many different component sizes.

The HILMA.ASH clamp has 80 mm of travel, so a single workholding arrangement can accommodate component families that would otherwise require investment in several different standard vices of more restricted travel. Therefore fewer conventional, workpiece-specific clamping devices are needed, saving expense. Set-up times are reduced and a further advantage is that spindle uptime is maximised on the machine tool.

The long travel offers sufficient flexibility for automated production of workpieces requiring more than one operation, while automated jaw change is possible using the same robot that loads and unloads the parts. It means that, without manual intervention, raw billets and semi-finished components can be held and machined alternately with different clamping forces.

On behalf of: Roemheld UK Ltd, 28 Knowl Piece,

Wilbury Way, Hitchin, Herts SG4 0TY

Tel: +44 (0)1462 459052

Fax: +44 (0)1462 438302

Contact: Terry O’Neill, Managing Director.

Email: Terry@Roemheld.co.uk

Web: www.roemheld.co.uk

Issued by: THE RIGHT IMAGE Ltd

PO Box 42, Twickenham, TW1 1BQ

Tel: +44 (0)20 8891 0603

Contact: Chris Wright

Email: chris@therightimage.net

Leave A Comment

You must be logged in to post a comment.