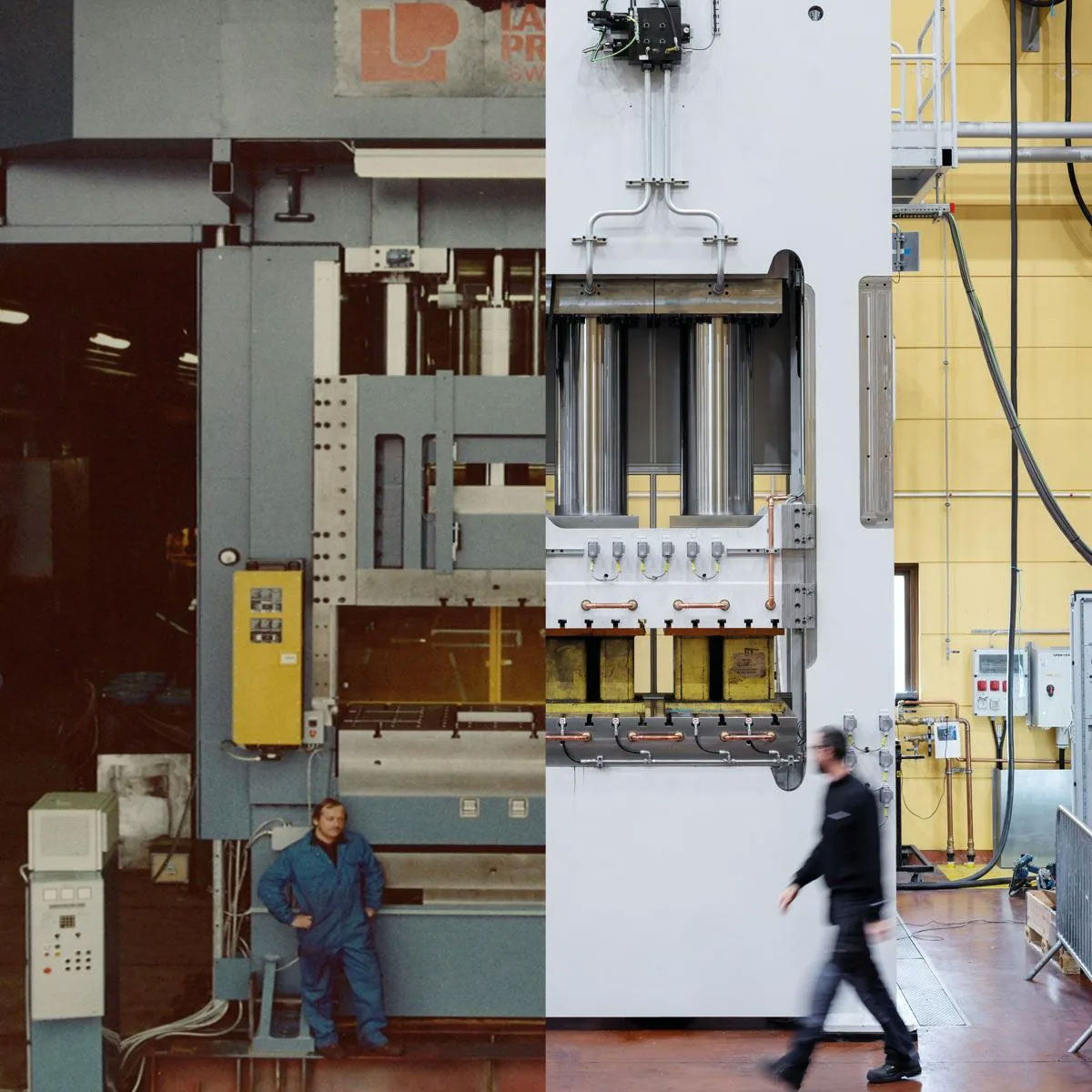

Presses past and present. On the left, a real heavyweight from Lagan Press, one of the three companies that eventually formed AP&T. On the right, a state-of-the-art AP&T press from 2024.

Take equal parts engineering, entrepreneurship and business acumen. Then add a rare ability to anticipate market needs, and you have a recipe for long-term success. For AP&T, which is an expert in metal and fiber forming production solutions and a preferred supplier to many leading manufacturers in the global automotive industry, this recipe has been working for 60 years. It transformed three small workshops in the Swedish countryside into a global actor.

When AP&T unveiled its production solution for cost-effective manufacturing of large, complex press-hardened parts earlier this year, it was, in a way, no surprise. Time and again, the company has demonstrated that it is a pioneer in the development of technological solutions that meet the challenges facing its customers, both in terms of productivity and sustainability. AP&T’s exceptionally energy-efficient servohydraulic press is one of many shining examples of what can be created in an innovative environment. The company’s solution for forming high-strength aluminum is another. Both have been added over the past ten years. During this period, AP&T has also renewed and expanded its automation program with a new generation of SpeedFeeders® for efficient sheet metal handling in various process steps—front of line, press to press, transfer, and end of line— and launched new generations of its Multi-Layer Furnaces. Innovation has gone hand in hand with continuous improvement, and the business has expanded with a range of services that all focus on providing customers with worry-free, profitable production over the lifetime of their equipment.

Looking back, we see that the inauguration of AP&T’s facility and headquarters in Ulricehamn in 2014 became the symbolic starting point for the successful ten-year journey that followed. But, in reality, it all started much earlier.

Global leader in press hardening

The tool manufacturer VIBAB was founded in Blidsberg in 1964, Lagan Press began to manufacture presses in Lagan the same year, and Tranemo Hydraulmaskiner was formed in 1970. In 1989, these three companies merged under the name AP&T (Automation, Presses & Tooling) and set their sights on the international market. This is also when AP&T laid the groundwork for its One Responsible Partner® concept, which has set the tone for the customer offer ever since. This concept manifests itself, for example, in AP&T’s willingness and ability to act as a fully responsible line integrator, regardless of whether the job entails a turnkey customer-optimized line from AP&T or the integration of new equipment from AP&T with existing or new machines from other manufacturers.

In the 1990s, the push to become a global actor began to pay off. Demand for AP&T’s production solutions increased rapidly, sales tripled, and AP&T established itself in several European countries and the USA. But it took until the early 2000s for development to really take off. That was when AP&T became a global leader in press hardening and a knowledge partner to be reckoned with in the global automotive industry.

AP&T has purposefully worked to strengthen this position in recent years, but it has also continuously developed its offering within both established niches, such as heat exchanger plates, and new niches, such as fiber forming.

Naturally, it is impossible to predict what will happen in the next 60 years. Development is a continuous process, and needs and challenges are changing all the time. Only one thing is certain: strong fundamental values will endure. But it is also always wise to peek ahead from time to time.

Leave A Comment

You must be logged in to post a comment.