AP&T is supplying automation to a brand new press line at Tenere’s production facility in Monterrey, Mexico.

Tenere, a North American manufacturer of custom mechanicals for tech companies, expands their operations in Monterrey, Mexico with a new production facility for metal part forming, AP&T is there to supply the automation.

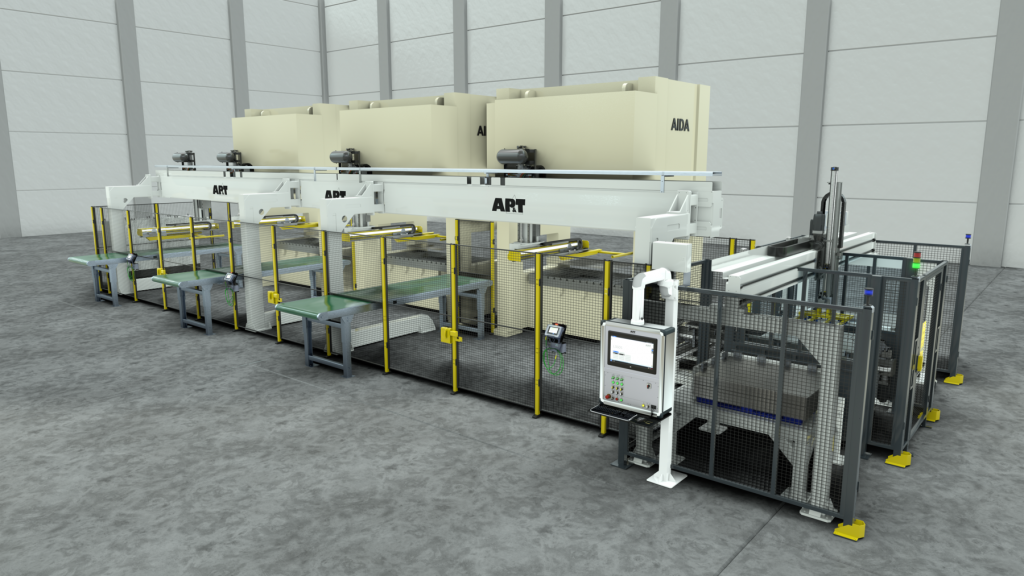

AP&T has taken on delivery, installation, integration and commissioning of all automation equipment included in the line. The start of production is planned for the first quarter of 2022.

“This investment will not only provide Tenere with new capabilities, stamping larger parts that we currently have to produce by other means, but also increase capacity in our stamping operations,” says Tenere’s Jeff Lunda, Director of Engineering, Tooling & Stamping.

“We are thrilled to have won Tenere’s confidence in managing their new line’s automation and we look forward to doing our part to make their production process productive and safe,” says Troy Hamilton, Regional Sales Manager of AP&T North America.

The AP&T undertaking includes a complete solution for quick, continuous blank feeding and four linear robots – SpeedFeeders – used to move blanks and components through the entire forming process. The SpeedFeeders are fully programmable on all axes and independent of each other, which allows easy introduction of new dies to the line. The line is also equipped with an AP&T electrical safety system.

The operator’s interface to the line is a panel similar to a PC with Windows-based software, which allows full control of the individual machines in the line and easy troubleshooting and communication.

“We have recognized the benefit of automation in several areas of our manufacturing facilities, and are excited to add this enhancement to our stamping operations,” says Jeff Lunda at Tenere.

Leave A Comment

You must be logged in to post a comment.