Following on from a successful MACH2018, Bruderer UK are again looking forward to the show this year in 2020.

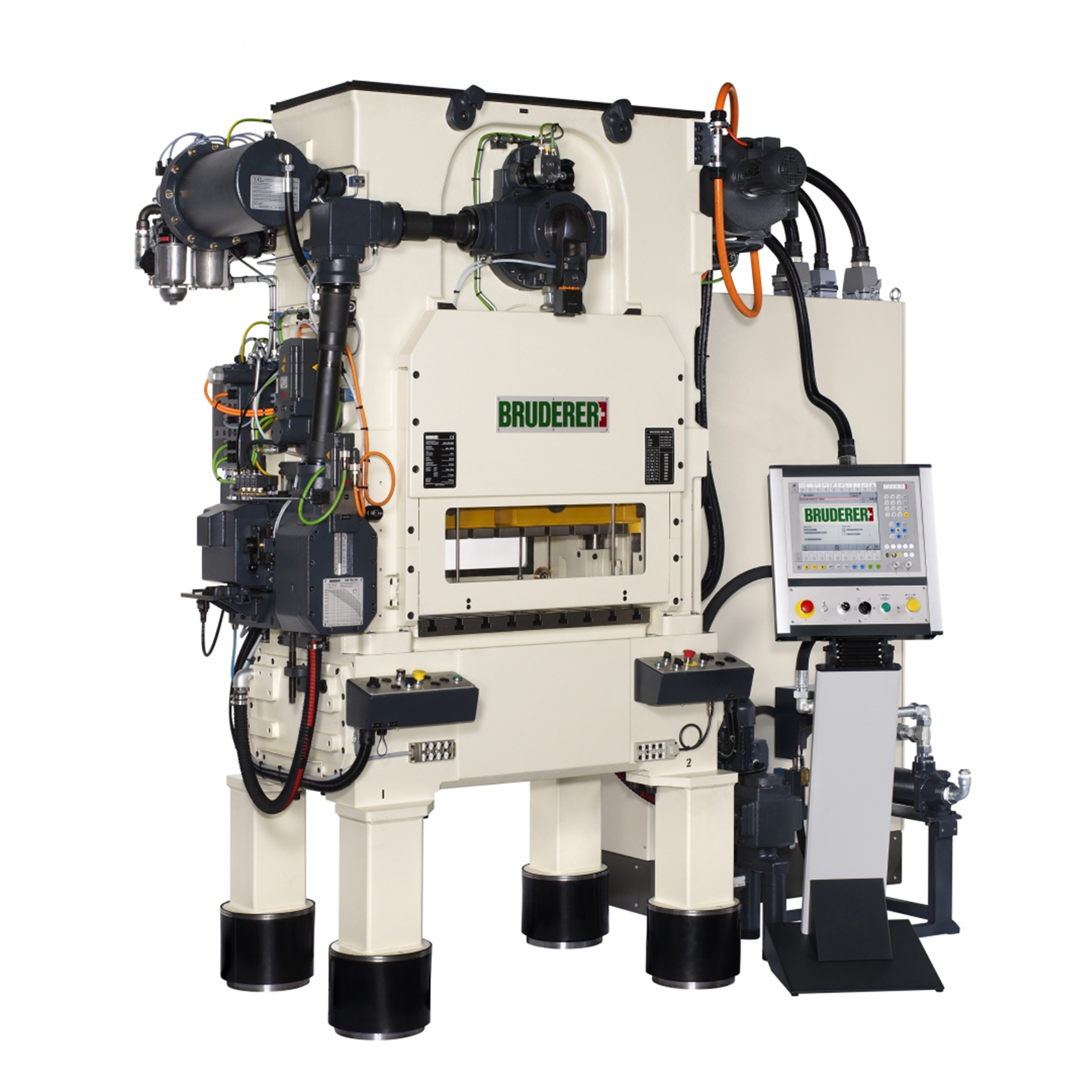

As always, our presence at MACH will be highlighted by a state of the art Bruderer high speed precision stamping press; this year we will be demonstrating a Bruderer BSTA 280-75B2 High Speed Stamping press, fitted with a BSV75 servo feeder and BPG planetary gearbox, demonstrating three presses in one. This will be running as a line with tooling & producing products, incorporating decoiler and rewinding equipment.

This year, we will also be featuring a new element to our portfolio, this being an in-line highspeed vision system for 100%-part inspection.

Also, we will be demonstrating the latest in servo feeder technologies, our range of world class press & mould tooling components, OEE system, lubrication equipment, press and tool monitoring systems, scrap transporters, tool and die handling equipment, to name just a few.

We feel the MMMA Metal working Village at Mach 2020 will be a great platform to show case state of the art technology within the precision stamping and forming sector for all Manufacturing companies to come and view first hand, and identify their needs for current production and new projects alike.

Since the election in December, we have noted an improvement in confidence in the market, and we believe a majority Government has helped to remove some of the uncertainty shrouding industry.

We believe that 2021 will be very different, with a lot of investments coming to fruition. There will be significant interest in the latest technology, Industry 4.0, which has been integrated into our machines for over a decade; this will also be in big demand as the clamour for real-time information and customer transparency across the entire production process grows including Single Minute Exchange of Dies (SMED) and state-of-the-art controls that mean up to 1000 tool store operations can be accessed and applied via a single touch.

Added to the benefit of supplying a machine that incorporates three machines in one, that being deep draw/forming, tool try out with micron adjustment for in-depth press tool development and of coarse high speed precision stamping machines to which we are synonymous with, gives our customers massive scope for future projects with unprecedented value for money.

Our Bruderer stand 20-269 will show case the latest developments for any manufacturing companies within the areas of power pressings (range of 10 ton to 2000ton), plastic moulding, press tool making, automation markets etc and we welcome everyone to come and see what we are about.

Leave A Comment

You must be logged in to post a comment.