Malvern Boilders Ltd. choose PX PLUS from CIDAN

Malvern Boilers Ltd is a successful Original Equipment Manufacturer (OEM) and developer of commercial water heaters, boilers, domestic pool heaters and MicroCHP appliances. For more than 30 years, Malvern has successfully worked with both start-ups and existing OEM companies that want to outsource their manufacturing requirements.

Why did you look for a new machine?

Our old machine had data transfer and backup issue. Also controls and programming were a struggle. Tool changes and crowning was incredibly time consuming, says Adam Heath, Operations Director.

Did you have other problems you wanted to solve?

Our production is a critical operation and we need reliable support for service and maintainance. We also had to adjust machines downstream to adapt to the wider tolerances from the old machine, says Adam Heath.

Why did you choose a FX PLUS from CIDAN Machinery?

It is important to constantly upgrade our machinery and keep up with developments. When we were going to replace an older folding machine with a new one, after a detailed search and selection process, the FX26 PLUS from CIDAN was selected for its balance of simplicity, accuracy and the ease of tool changing offered by its COMBI beam, says Adam.

In what way will the FX PLUS benefit for your production?

The machine has a little extra in several areas, it is very flexible with multiple points of adjustment, the software is easy to use for both programming and operation and Malvern Boilers now has greater flexibility for future production and design innovation. To make it easier for the operator, the machine has a COMBI upper beam that provides easy and quick tool changes. Malvern Boilers has production that requires many tool changes, short series, and lots of adjustments of the tooling, so savings in these areas have a strong impact on production efficiency.

What other advantages do you like?

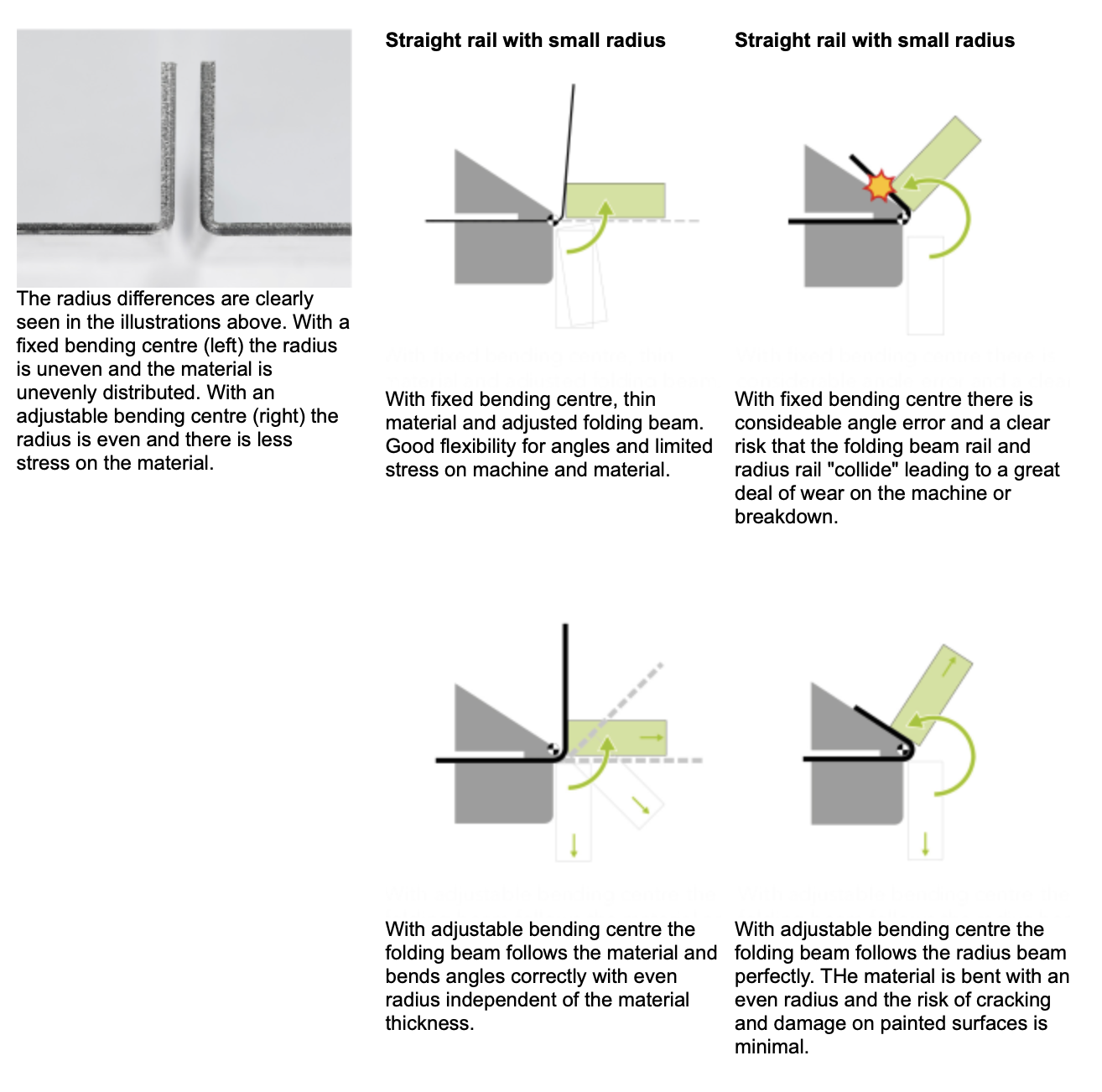

The machine is also equipped with an L-shaped back gauge that can be positioned up to 3300 mm. The operator does not have to follow the sheet during bending, large sheets can be handled with just one operator. The machine has as an option called PLUS, with automatic sheet thickness adjustment and automatic adjustment of the bending center, this gives the best possible bending results regardless of material and thickness.

Can you summarize your experience from purchasing a FX PLUS from CIDAN Machinery?

Support from CIDAN offers greater peace of mind with experts engineers able to access the machine directly from remote location for diagnosis purpose. Great accuracy of produced parts means minimal adjustments in the coming machines. We also moved larger sheets handled on press brake to FX PLUS, reducing sheet handling with a consequent reduction in risk and improvement in ergonomics, protecting our employees when they handle heavier parts, says Adam Heath.

Leave A Comment

You must be logged in to post a comment.