An improved range of hydraulically-actuated, double-acting arch clamps has been introduced by Roemheld (UK) for securing moulds and dies with straight edges to the bed and ram of plastic injection moulding and die casting machines, forging and rubber moulding presses, and sheet metal forming machines. They are suitable for use in environments from ambient temperature up to 250°C.

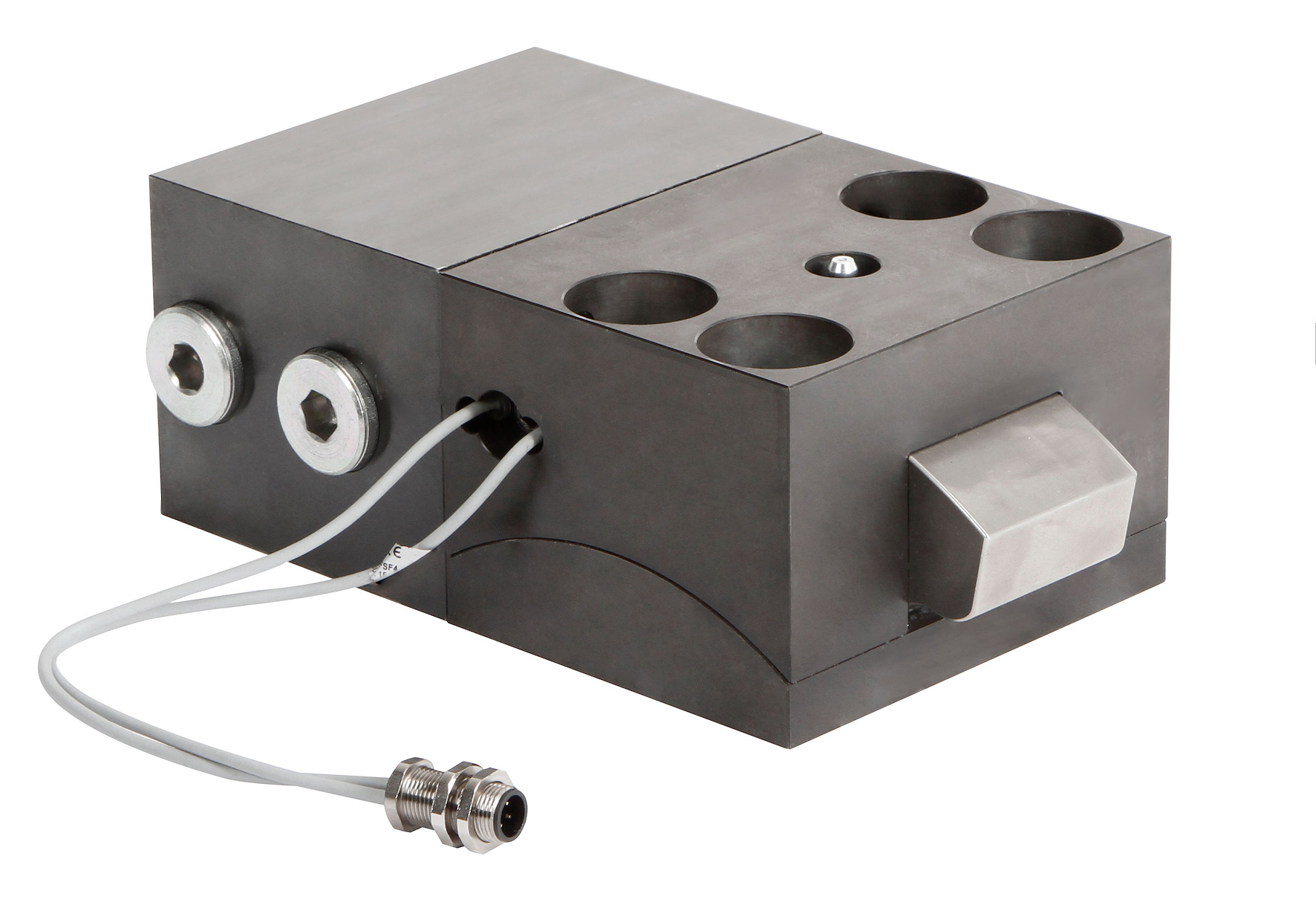

One of the improved arch clamps from Roemheld.

Manufactured in Germany and competitively-priced, the sturdy clamps are available in seven versions and have the standard option of integrated position monitoring for use up to 100°C. For special applications, it is possible to use position monitoring with sequence valve control up to 250°C. The facility affords particularly high process reliability, as it informs the operator as to whether the tool is retained or not and whether the clamping position is overrun.

Consisting of a hydraulic block cylinder and piston, the units are named after the arch-shaped bolt that secures the tool. During clamping, the horizontally acting force is translated into an almost vertical movement. The clamps are treated with a long-lasting, corrosion-resistant coating to ensure excellent sliding properties. As a result, the bolt releases effortlessly and reliably even under the most demanding use.

An integrated mechanical lock ensures that the tool is held reliably, even in the event of pressure loss. This is especially important for the ram to ensure that the tool cannot fall and cause damage or injury. Clamping and unclamping pressures are 200 bar in each case and the clamping force is between 30 and 450 kN, depending on the model.

Leave A Comment

You must be logged in to post a comment.