Craven Fawcett, one of the UK’s leading manufacturers of clay preparation machinery and part of Group Rhodes, has added a new model to its extruder line up, with the capability to deliver higher volume outputs.

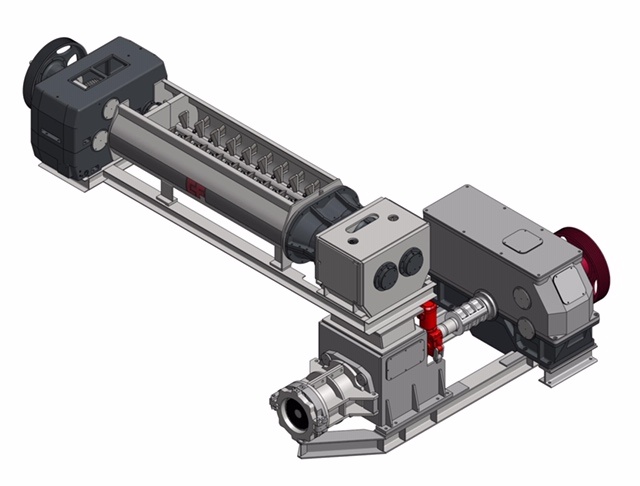

The name CENTRA, which references multiple centres, reflects the machines ability to split its de-airing chamber to allow the mixer to be mounted either in-line or at 90 degrees to the extruder. The Double Shafted Mixer section has also been upgraded with the inclusion of a new design of gearbox and larger trough to complement the machine’s enhanced capacity of up to 25,000 bricks per hour.

The new CENTRA model retains the reliability of Craven Fawcett’s tried and trusted range of extruders and includes the capability of fitting larger diameter worms (flighted screws), from 430mm up to 650mm to suit a wide range of applications. It also features independent packer shaft drives which enables easy access for maintenance, and allows more power to be available from the extruder gearbox to transmit to the main extruder auger shaft.

Glynn Dixon, Contracts Manager at Craven Fawcett, said: “This newly designed and innovative extruder offers higher output volumes, easy access and low maintenance. We responded to customer demand by developing the CENTRA, which is suitable for a wide range of applications, but particularly in the production of bricks and hollow blocks.”

The new CENTRA Extruder has a larger mixing capacity, offers low maintenance and has a more flexible design. It features two separate gearboxes for ease of maintenance access and provides more homogenous mixing capabilities. The extruder itself is also more compact, taking up a footprint of just 6 metres long, compared with 8.5 metres on similar machines.

Easy access to worms and liners is provided by CENTRA’s hinged extruder barrel, a key part of its low maintenance design. In addition, wear liners are available for the Mixer trough in order to enhance the extruder’s durability.

CENTRA’s rigid cast iron gearboxes are fitted with heavy duty bearings and helical gears throughout.

All Craven Fawcett extruder worm sections are subjected to a combination of in-house treatments to ensure energy minimisation, longevity and component quality. After being cast, each worm section undergoes a unique heat treatment process in our own high temperature ovens in order to ensure an even distribution of chrome throughout the component and enhance its longevity.

The machine is suitable for the production of stiff extruded bricks, semi-stiff hollow blocks and various pelletised products, such as iron ore.

Craven Fawcett has supplied extruders and other machinery to the brick and clay pipe manufacturing industry for over 175 years and is at the forefront of technology in the field of various extruded products

The company manufactures a range of special equipment including Box Feeders, Grinding Mills, Mixers & Extruders sold globally for the heavy clay and ceramics industry, as well as the mining and quarrying industries.

Alongside high-quality Original Equipment Manufacturer (OEM) products and services, Craven Fawcett offers guidance on material selection, component finish and supply of spare parts in order to optimise production efficiency and reduce the frequency of machinery repair. This is backed by a team of highly trained and experienced service engineers dedicated to clay preparation machinery, who can repair and maintain Craven Fawcett equipment both on and off site.

For further details visit the website www.craven fawcett.co.uk or call 0 (+44) 1924 37544

Leave A Comment

You must be logged in to post a comment.