There are some die transport carts on the market, usually models with low functionality. Few carts are optimised for a mould change, and in limited spaces or with high loads, most of them quickly reach their limits. This is different with automotive supplier ElringKlinger. The company has recently started using a compact model from ROEMHELD adapted to the individual requirements.

ElringKlinger AG is a listed automotive supplier with over 10,000 employees at 45 locations worldwide. The company headquarters are located in Dettingen/Erms, Baden-Württemberg. At this site, the company produces cylinder-head gaskets, among other products, for which ElringKlinger remains the world market leader to this day. The company also produces special gaskets for engines, transmissions and exhaust systems as well as lightweight plastic components such as oil pans and cam covers. The latter product group is part of the lightweight construction/elastomer technology division, which is now ElringKlinger’s top-selling segment.

“Over the last few years, we have grown steadily, so we needed more and more space. As a result, we are sometimes faced with very cramped conditions,” says Tobias Gerst, production engineer in the lightweight construction/elastomer technology division. He is responsible for the procurement of machines and plants as well as for the planning and optimisation of production processes.

The space is particularly cramped, for example, at two injection moulding machines, equipped by a common robot and running in three shifts. They are located in an enclosure which can only be entered through a comparatively narrow and low door for the mould change. Directly in front of the machine, there is hardly any space left for manoeuvring a transport cart. In the past, this used to cause a challenging and physically exhausting mould change – which is now noticeably easier due to a compact transport cart from ROEMHELD.

Standard changing cart as an emergency solution

On the two machines, which are positioned at an angle of about 120 degrees to each other, among other things, transmission gaskets are provided with sealing lips made of an elastomer. Every eight to nine days, it is time for a mould change. Since there is no overhead crane in the hall, the machines cannot be loaded from above. Instead, the plant operators used one of the many standard transport carts used in plant 1 until a few months ago. For production engineer Gerst, however, this was an emergency solution: “The existing cart types were either unsuitable for high mould weights or too large for the limited space available. As a result, we had to manoeuvre awkwardly and still could not quite reach one of the two machine tables.”

Therefore, the injection moulding machine was approached from the side instead. However, this meant that the moulds had to be pushed crosswise to the roller bars of the changing cart. A lot of muscle strength was required until the mould was finally in the right place. Therefore, two years ago, Gerst looked for an alternative that better met the special requirements.

Moulds weigh up to one tonne

The steel moulds used on the two machines weigh up to one tonne and have a maximum height of 400 mm. The size of the base area varies between 300 mm x 300 mm and 550 mm x 500 mm. Of course, the new changing cart should be equally suitable for small and large moulds – and still fit through the enclosure’s narrow door.

“We were also looking for a system where we could push out moulds in several directions,” adds Gerst. This saves the operator from having to manoeuvre, regardless of which injection moulding machine he is changing the mould. One is located to the right of the entrance to the enclosure, and the other is opposite it. The operator can drive in a straight line, load and unload the cart forwards and to the right, and drive out in reverse gear.

Google provided the solution

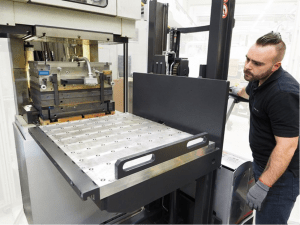

Through a Google search, Gerst came across the clamping and changing technology manufacturer ROEMHELD. The group of companies with its headquarters in Laubach is one of the leading set-up time optimisers for the plastics processing industry worldwide. They develop and distribute the die changing cart RWA 1600, which is characterised by a compact design, an electro-hydraulic lifting platform and a shuttle table equipped with hydraulic ball bars. The cart can also be adapted to specific customer requirements.

Due to the ball bars in the support surface, dies can be moved manually in any direction. A special mechanism ensures transport safety: During transport, the ball inserts are lowered and the die is protected against movement. Insertable front and side bars provide an additional safety measure.

Special requests quickly considered

As standard, ROEMHELD offers three versions with four, six or eight ball bars and a load capacity of 1,600 kg each. After a detailed consultation, however, Gerst decided on a special version with nine roller bars. This ensures that even the smallest moulds used by ElringKlinger are securely supported by at least two bars. The production engineer also opted for a smaller plate 850 mm wide and 750 mm deep instead of the standard size of 1,150 x 800 mm. This size is sufficient for the moulds used at ElringKlinger and allows the operator to pass through narrow passages without difficulty. The cart has also been adapted to suit the low door lintel. For this purpose, its mast was shortened by 10 cm to 190 cm.

“An essential criterion in our decision was that we were able to configure the die changing cart to match our situation and requirements exactly. The cart is suitable for small moulds as well as large and heavy moulds and enables mould changes to be carried out quickly and easily in limited spaces. The standard version of ROEMHELD’s RWA 1600 almost matched our application profile. Also, the company took intensive care of us and convinced us with advice and service.”

Back-protecting mould change

Shortly before Christmas, the new die changing cart was delivered. Plant fitter Fethi Bennadji was delighted: “The cart is a great relief for us. Before, the mould change was challenging and exhausting, but now the balls on the lifting platform protect the back. The cart is also sturdy and easy to handle.”

For this purpose, the cart has a multi-functional drawbar on which the lifting platform and the electric drive can be operated. The speed of the cart can be continuously adjusted up to 5 km/h. For tricky spots, there is also a “creep speed” of 2 km/h, which can be selected using a toggle switch. When braking, energy is recovered to save the battery. Besides the drive, the battery also supplies the hydraulic system of the lifting platform and the ball bars with power.

Replaceable battery

With a charge of 240 Ah, the battery can supply the cart for about three hours at maximum speed with a full load. The battery can then be fully charged within twelve hours. If the cart is to continue driving straight away, it can be replaced with a full battery in a few simple steps.

“We are delighted with the cart and would rebuy it at any time”, reports Gerst. Not only because of the tight enclosure for which the cart was originally purchased: thanks to its high load capacity and compact design, the RWA 1600 can be used on many installations in plant 1.

Further information:

ROEMHELD: Set-up time optimiser for sheet metal forming, plastic and rubber processing

With its extensive portfolio of die clamping technology, the set-up time optimiser ROEMHELD solves almost every clamping task in sheet metal forming, plastics and rubber processing. The magnetic, hydraulic and electro-mechanical clamping systems are versatile and contribute to making processes in single and series production of nearly all industries more efficient and economical. Products for die change such as die changing carts, roller bars and driven carrying consoles complete the product range.

About ROEMHELD:

Whether for aircraft, automobiles, machine tools or cases for smartphones: technologies and products of the ROEMHELD Group have been used to manufacture numerous industrial commodities and goods for end users for more than 60 years.

Efficient clamping technology solutions for workpieces, as well as for dies in forming technology and plastics processing, form the core of our ever-increasing portfolio. This is supplemented with components and systems for assembly and handling technology, drive technology and automation as well as locking mechanisms for rotors on wind energy systems.

In addition to a constantly growing range of more than 30,000 catalogue items, the ROEMHELD Group also specialises in the development and realisation of customised solutions and is internationally regarded as one of the market and quality leaders.

Innovation through tradition: ROEMHELD was established in 1707 with a foundry in Friedrichshütte, which still belongs to the ROEMHELD Group today and counts as one of the oldest active industrial businesses in Germany.

The owner-managed group of companies employs approximately 560 workers in its three locations of Laubach, Hilchenbach and Rankweil/Austria, and is represented in over 50 countries by service and sales organisations. With customers from the mechanical engineering sector, as well as the automobile, aviation and agricultural industries, the ROEMHELD Group generates an annual turnover of more than 110 million Euro.

Contact person:

Andreas Reich

Product manager Die clamping technology

Hilma-Römheld GmbH

Schützenstraße 74, D-57271 Hilchenbach

Tel.: +49 2733 281 162

E-mail: a.reich@hilma.de

www.roemheld-gruppe.de

by F. Stephan Auch, freelance specialist journalist from Nuremberg.

Video of the RWA 1600 die changing cart:

https://www.youtube.com/watch?v=XmzbJ8hoA7o

Leave A Comment

You must be logged in to post a comment.