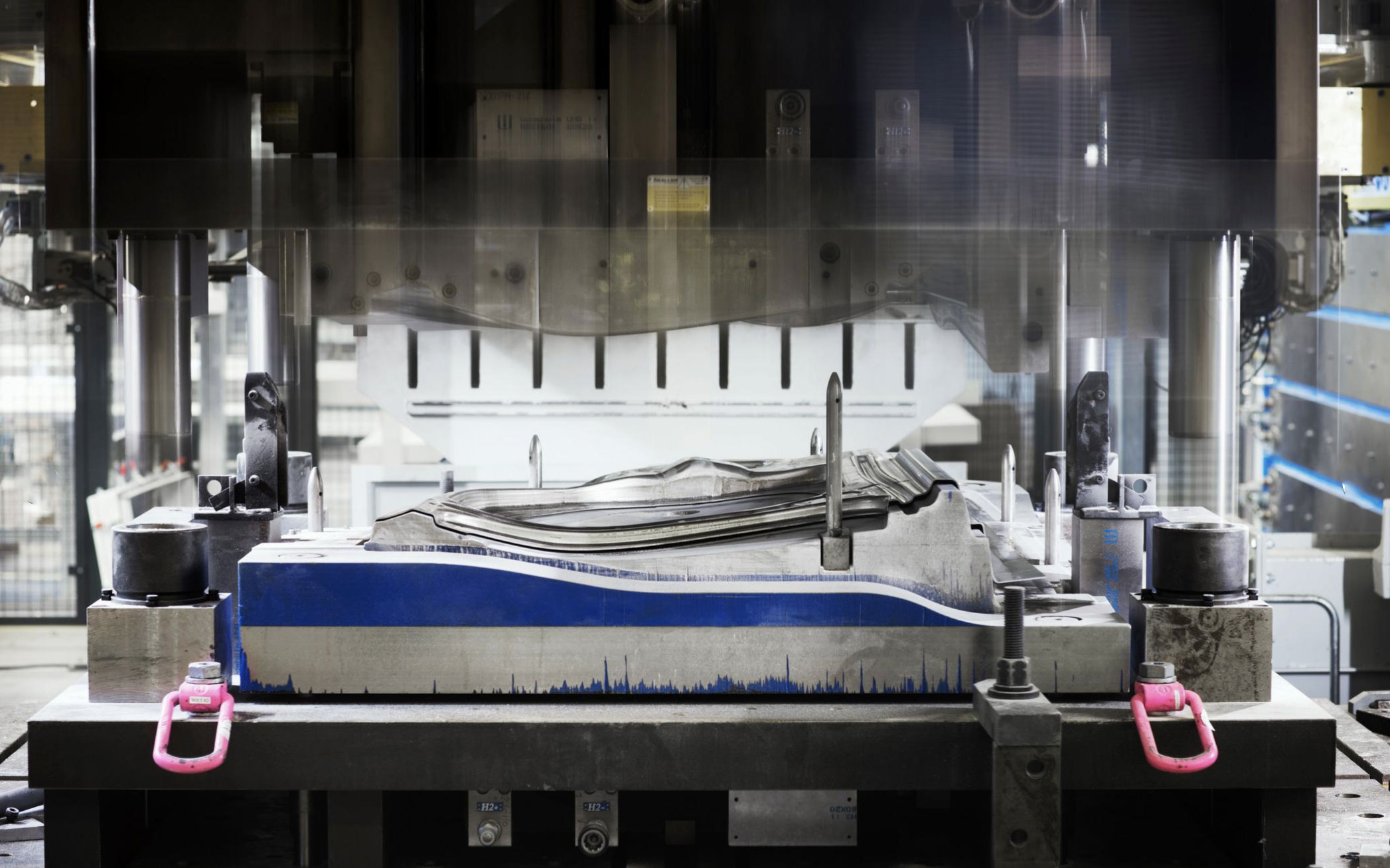

Streamline your production with KALLER multi-tool for effective flanging

Are you interested in streamlining your production and lowering your costs? Find out how this can be achieved with our multi-tool for effective flanging here. With smart, simplified tool design KALLER has made it possible to combine functions in [...]